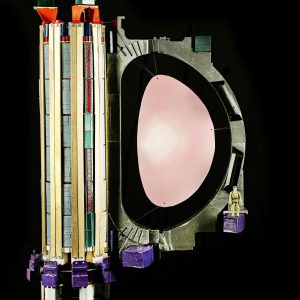

Building the heartbeat of ITER: Preparing a unique fabrication line for the central solenoid modules

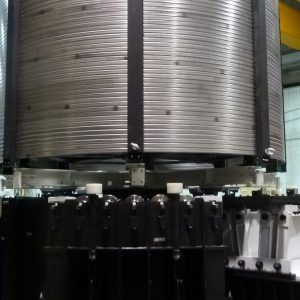

―Lynne Degitz With winding of the first production module for ITER’s central solenoid well underway, US ITER and its contractor, General Atomics, are now commissioning all of the necessary tooling stations for the 13 Tesla 1,000 metric ton electromagnet. Eleven unique stations will form the module manufacturing line at the GA Magnet Technologies Center, a […]