ITER, the world’s first reactor-scale fusion machine, will have a plasma volume more than 10 times that of the next largest tokamak, JET. Plasma disruptions that can occur in a tokamak when the plasma becomes unstable can potentially damage plasma-facing surfaces of the machine. To lessen the impact of high energy plasma disruptions, US ITER is engaged in a global research effort to develop disruption mitigation strategies.

US ITER, managed by Oak Ridge National Laboratory, will continue working closely with global partners on the ITER disruption mitigation system, as the 2016 deadline for design of the system rapidly approaches. To continue moving R&D forward, an early conceptual design review was supported by US ITER in November.

Larry Baylor, a distinguished scientist in ORNL’s Fusion Energy Division, says that the disruption mitigation system needs to accomplish two main objectives: To reduce the thermal energy of the plasma and to diminish the effects of “runaway electrons” that can form as a result of the disruption.

“A disruption occurs when the plasma becomes unstable and starts to move uncontrollably. You have to cool the plasma down quickly so that it does not hit the wall with that thermal energy,” notes Baylor. “Tokamaks have a current inside the plasma. In a disruption, that current decays fairly quickly and it has a side effect of generating a voltage in the plasma, called a ‘loop voltage.’ And that loop voltage can cause electrons that are already in the plasma to speed up to very high energies. We call those runaway electrons.”

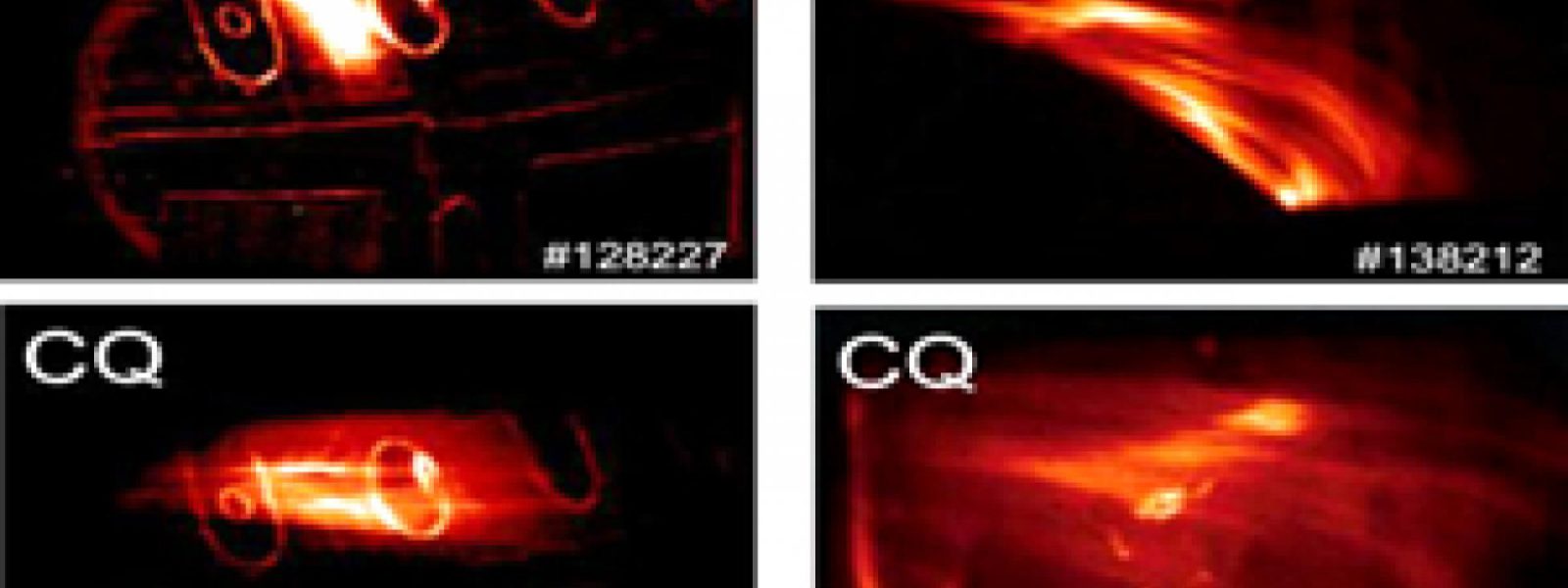

Two main concepts are under consideration for disruption mitigation. Massive gas injection quickly injects gases such as neon or argon into the plasma. Shattered pellet injection uses wine cork-sized cryogenic pellets, mostly of neon and deuterium, to insert many small fragments of solid along with gas and liquid into the plasma. For both concepts, it is crucial that the system respond very quickly to potential disruptions.

Earlier in 2012, Nicolas Commaux, an ORNL fusion energy scientist, was awarded a $2.5 million early career grant by the DOE Office of Science for further work on disruption systems. Commaux notes that important findings have been made about how to use massive gas injection to affect the location and behavior of electron beams in the plasma. Investigations are on-going and further developments are anticipated in 2013.

Much of the research within the US has been taking place at DIII-D, a tokamak managed by General Atomics for the Department of Energy in San Diego, Calif. This tokamak offers a number of advantages for disruption studies, as it is compact and extremely resilient.

Commaux observes, “Disruption mitigation experiments are usually rather unpopular for the machine because we deliberately trigger disruptions. But DIII-D is well equipped with thick carbon tiles to protect the walls.”

Media Contact: Lynne Degitz or @US_ITER